The term ‘sprayed concrete’ refers to a method of applying concrete using pressurized and compressed air. The resulting structure is generally self-supporting and does not rely on form work.

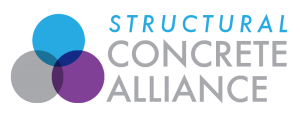

There are three main processes for the application of sprayed concrete: wet, dry, and robotic.

Dry Process

Dry material pneumatically conveyed to the water injection nozzle.

Wet Process

Fluid material pumped to the air injection nozzle.

Robotics

Stand alone nozzle manipulators or fully integrated pump and nozzle units.

Early applications of sprayed concrete were for reinforced concrete repair work. Soon its advantages were adopted for new construction.

Sprayed concrete was developed by Dr Carlton Akeley around the turn of the 20th century.

The early machines placed the dry mix of sand and cement into the pressurized chamber from where it was projected to a nozzle where water was added. This system was therefore termed the “dry process”.

As the dry process was being developed the “True Gun” method was also being developed. This required the sand and cement mixture to be fully mixed with water before being pumped through a fundamentally different machine. Because of its different mixing method the system became known as the “wet process”. The wet process was not fully developed commercially until well into the 1970s, much of its experimentation being carried out in the USA.

Recent developments in robotic technology in manufacturing industries has led to the introduction of robotic concrete spraying machines which come as either stand alone nozzle manipulators or fully-integrated pump and nozzle units. Such technology requires no manual handling of hoses, leading to increased productivity.

The acceptance and use of sprayed concrete is now worldwide. The processes allow complex shapes and structures to be formed without the high costs associated with formwork.

With sprayed concrete the Designer can have the freedom to achieve almost any shape. The Specifier should ensure that adequate plans with detailed dimensions are provided. This will enable the Contractor to accurately assess the Specifier’s requirements.